Milling screens

High throughput and consistent results

Round hole perforation is the most widely used pattern for hammer mill screens, valued for its durability, strength and versatility. Customised hammer mill screens with round holes are ideal for processes where consistent particle size, reliable throughput, and long-term durability are crucial.

RMIG Solutions offers the world’s most extensive selection of hammer mill screens with round hole patterns, including hole sizes from 0.50 mm to over 10 mm. No matter your industry, from feed milling and recycling to pet food and aquaculture, our hammer mill screens can be customised to match your exact requirements.

With custom-made hammer mill screens from RMIG Solutions, you can optimise your milling processes for greater efficiency:

-

Higher throughput, less waste: Optimised open area and smart pattern layout help you process more material per hour while lowering energy usage.

-

Consistent milling results: Tight tolerances and precise perforation deliver uniform particle size and fewer process disruptions.

-

Extended screen lifetime: Screens with hole diameters smaller than, or equal to, the sheet thickness last longer and require fewer replacements.

-

Faster, easier screen changes: Ready-to-fit screens let you swap out quickly and minimise downtime.

RMIG Solutions round hole hammer mill screens support both fine grinding and high-output needs, without compromising on efficiency or durability. For applications in tough operating conditions, we offer screens made from through-hardened material.

With the right screen, your milling process becomes more predictable, more productive, and more cost-effective.

Milling productivity and quality

Thicker screens, finer control

The thicker the screen, the smaller the particles must be to pass. This makes screen thickness important, especially when hole sizes are below 2.0 mm.

Thicker screens improve durability, but milling performance also depends on hole size, layout, and total open area.

While a higher open area can boost throughput, it may reduce structural strength, so balancing these factors is key to achieving consistent, efficient results.

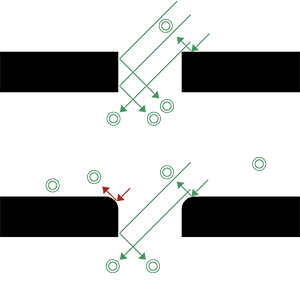

Sharper edges, better performance

Efficiency drops when screens wear out. Sharp-edged holes cut more effectively than worn, rounded edges.

The back side of a perforated screen typically has sharper edges, so correct orientation improves throughput and minimises clogging.

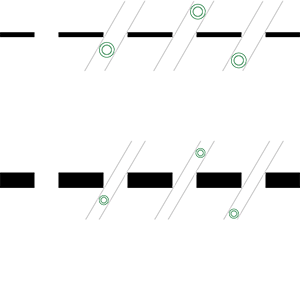

Optimised layout, higher output

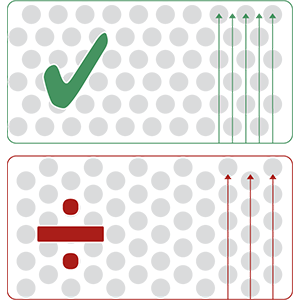

Productivity depends on how the perforated screen is turned.

By using the optimal hole layout placed in the right direction, you increase the likelihood of particles finding a hole and consequently the milling speed is faster – up to 25% higher productivity.

As shown by the arrows in the illustration, particles pass more holes when the screen is turned in the green direction. This small adjustment translates into significant gains in processing speed and efficiency.

Examples of our products

Round hole perforation for hammer mill screens

| Pattern | Hole size (R) mm | Pitch (T) mm | Open area % | Thickness mm | Variant (special) | |

| AQUA FEED | R0.5T1.09 | 0.50 | 1.09 | 19.0 | 0.50 | |

| AQUA FEED | R0.5T1.25 | 0.50 | 1.25 | 14.5 | 0.50 | |

| AQUA FEED | R0.75T1.5 | 0.75 | 1.50 | 22.7 | 0.75 | 1.00 mm thickness |

| AQUA FEED | RO.8T1.3 | 0.80 | 1.30 | 34.3 | 0.75 | 1.00 mm thickness |

| AQUA FEED | R0.8T1.5 | 0.80 | 1.50 | 25.8 | 0.75 | 1.00 mm thickness |

| AQUA FEED | R1T1.75 | 1.00 | 1.75 | 29.6 | 1.00 | 1.25 mm thickness |

| AQUA FEED | R1T2 | 1.00 | 2.00 | 22.7 | 1.00 | 1.25 / 1.50 mm thickness |

| AQUA FEED | R1.1T2 | 1.10 | 2.00 | 27.4 | 1.00 | 1.25 / 1.50 mm thickness |

| AQUA FEED | R1.2T2 | 1.20 | 2.00 | 32.7 | 1.00 | |

| AQUA FEED | R1.25T2 | 1.25 | 2.00 | 35.4 | 1.00 | 1.25 mm thickness |

| AQUA FEED | R1.25T2.4 | 1.25 | 2.40 | 24.6 | 1.00 | 1.25 / 1.50 mm thickness |

| AQUA FEED & PET FOOD |

R1.3T2 | 1.30 | 2.00 | 38.3 | 1.00 | |

| PET FOOD | R1.5T2 | 1.50 | 2.00 | 51.0 | 1.00 | |

| PET FOOD | R1.5T2.5 | 1.50 | 2.50 | 32.6 | 1.50 | |

| AQUA FEED & PET FOOD |

R1.5T3 | 1.50 | 3.00 | 22.7 | 1.50 | 2.00 mm thickness |

| PET FOOD | R1.6T2.4 | 1.60 | 2.40 | 40.3 | 1.50 | |

| PET FOOD | R1.75T3 | 1.75 | 3.00 | 30.9 | 1.50 | 2.00 mm thickness |

| PET FOOD | R2T3 | 2.00 | 3.00 | 40.3 | 2.00 | 2.50 mm thickness |

| PET FOOD | R2T3.5 | 2.00 | 3.50 | 29.6 | 2.00 | 2.50 mm thickness |

| R2.25T3.3 | 2.25 | 3.30 | 42.3 | 2.00 | 2.50 mm thickness | |

| R2.25T4 | 2.25 | 4.00 | 28.7 | 2.00 | ||

| R2.5T3.3 | 2.50 | 3.30 | 52.1 | 2.00 | ||

| R2.5T3.5 | 2.50 | 3.50 | 46.3 | 2.50 | ||

| R2.5T4 | 2.50 | 4.00 | 35.4 | 2.00 | ||

| R2.75T4.5 | 2.75 | 4.50 | 33.9 | 2.00 | ||

| R3T4 | 3.00 | 4.00 | 51.0 | 3.00 | ||

| R3T4.5 | 3.00 | 4.50 | 40.3 | 3.00 | ||

| R3T5 | 3.00 | 5.00 | 32.6 | 3.00 | 4.00 mm thickness | |

| R3T5.6 | 3.00 | 5.60 | 26.0 | 3.00 | ||

| R3.25T5.25 | 3.25 | 5.25 | 34.8 | 3.00 | ||

| R3.5T4.5 | 3.50 | 4.50 | 55.0 | 3.00 | ||

| R3.5T5.5 | 3.50 | 5.50 | 36.7 | 3.00 | ||

| R4T5.25 | 4.00 | 5.25 | 52.7 | 3.00 | ||

| R4T6 | 4.00 | 6.00 | 40.3 | 4.00 | ||

| R5T8 | 5.00 | 8.00 | 35.4 | 5.00 | ||

| R6T12 | 6.00 | 12.00 | 22.7 | 6.00 | incl. Weldox | |